New Flooring

New Flooring

It is important that you know the key differences in each flooring type when making the important choice of what flooring you will be living with for many years to come. We can provide the materials or install your own flooring.

Common Wood Flooring Types

There are three basic types of wood flooring:

- Solid (raw)

- Engineered (pre-finished)

- Laminate

Solid Hardwood

Solid wood flooring is the traditional style of wood flooring. This type of flooring is installed by a nail-down installation method over wood subfloors. You choose the custom stain and it is finished to match your decor or preference. This is known as “Job Site Finished” wood.

Solid hardwoods are typically 3/4" thick, although some do come in 3/8" or 5/16" thicknesses. Our most popular product is the 3/4" red or white oak. It comes in a variety of widths with 2 ¼” the most common.

Some other types of raw flooring are maple, pine, hickory, pecan, and cherry. There is also bamboo, which is technically not a wood, but can be made into flooring with many of the same properties as wood.

Unfinished hardwood flooring is delivered raw then sanded, stained and finished on site. It is available in more widths and wood species than prefinished flooring, and can be matched to existing wood floors. Solid wood can be sanded and refinished many times removing scratches or imperfections to make like new.

A custom sanded hardwood floor is perfectly flat looking, with a tabletop appearance that cannot be achieved with a pre-finished hardwood floor. If the subfloor is uneven, then a pre-finished or laminated floor will be uneven. Since the unfinished flooring is sanded flat on site, it is more forgiving of slight irregularities in the subfloor.

Engineered Hardwood (Pre-Finished)

Rather than having one solid piece of hardwood, the engineered hardwood method uses layers of hardwood veneer to create a product that can range in thickness from 3/8" or 8mm up to 9/16" or 14mm thick, depending on manufacturer.

Engineered hardwood can be glued directly to concrete above or below grade, as opposed to solid hardwood which cannot. This type of flooring already has the stain color baked on at the factory. Engineered wood floors that are at least 3/8” in thickness or more can generally be refinished one or two times. The rule of thumb – the thicker the floor, the more times it can be refinished.

You will also see a beveled edge on this type, which is to draw your eye away from the floor being uneven from not being sanded on site to match the contours of your subfloor. Having these beveled edges require more maintenance when cleaning, because they tend to collect more dirt than the smooth job site finished floors. You also do not have perfect tabletop look of a custom job site finished floor.

Laminate / Floating Flooring

Laminate flooring is made to look like natural products such as wood flooring or natural stone, yet is made up of either synthetic materials (usually melamine resin) or of synthetic materials combined with natural and recycled ingredients and covered with an attached decorative appliqué including an aluminum oxide finish.

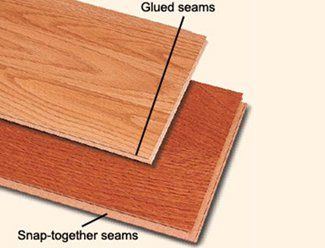

A laminate floating floor can be installed without the use of nails and sometimes glue. It cannot be refinished however, so if it is scratched or damaged, it must be replaced and you may have color match issues due to fading if you try to just replace one area. It also does not have as “solid” of a feel as hardwood when walking on it.

5406 G Road, Waterloo, IL 62298 ● 618-567-5411 ● Email Address: qualitywoodflooring@yahoo.com

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy